Lab Operations in a Post-COVID-19 Landscape

The pandemic has seen unprecedented staff shortages plague every industry, as well as forcing businesses to adapt their practices to comply with social distancing regulations while attempting to maintain day-to-day operations. The sciences have previously resisted shifts towards hybrid work models, with many tasks requiring in-person attendance at the lab. However, the pandemic has accelerated the digitization of many lab operations and spurred increased buy-in of automation, marking a substantial change in attitudes towards lab operations post-COVID, and significant innovations in facilitating remote work.

Challenges in Lab Management in The Pandemic Landscape

Managing Remote Staff

Lab managers have had to overcome a number of challenges in maintaining the ‘new normal’ in lab operations in the face of staff shortages, stringent social distancing measures, and unrelenting workloads. Lab Manager notes some of the speedbumps in adjusting to the pandemic, notably supporting staff with the challenges in remote work and leading teams virtually, adequately staffing labs while remaining compliant with social distancing as well as remediating staff COVID absences and having to shelve projects to keep up with increased workloads. Managers have had to learn to use and standardize digital tools to communicate and coordinate with staff working remotely, while incorporating flexibility into a previously non-hybrid industry. An increase in remote working has been associated with negative impacts on the mental health of staff – with less distinction between when the workday starts and ends, staff are less able to distance themselves from work, even once logged off.

Staffing Shortages

Staffing shortages have been another significant hurdle for lab managers to navigate, and show little sign of letting up. The Great Resignation, as well as COVID factors, have led to significant staff shortages across the industry – and with a globally aging population, the volume of sample processing is continuing to increase while the qualified workforce shrinks. There is a difficulty in recruiting graduates quickly enough to fill roles – and scientists that do fill roles may ultimately be employed in carrying out monotonous and unfulfilling tasks that can become costly in terms of opportunity cost and do little to advance wider lab outcomes. It is important to consider the effects of this work on new hires, given that “adequately valuing the education level of lab employees and delegating the appropriate kinds of work to automation technologies effectively helps labs do more with less while keeping staff satisfied and engaged in their work too.”

How COVID-19 Has Changed Lab Operations

How COVID-19 Has Changed Lab Operations

Reduced In-Lab Attendance

Lab managers have had to rethink how to conduct lab operations in the face of COVID-19 and social distancing restrictions, given that “the amount of time staff spend physically present in the laboratory has significantly reduced over the past 12 months” (2021). The day-to-day running of labs has changed – more space is needed between equipment stations, adequate heating and ventilation is crucial, and extensive sanitization and deep cleaning protocols are now in place. Projects, work tasks, operational prep, and instrument use, are all assigned and managed to keep in-lab personnel to a minimum at all times. These measures have seen increased use of scheduling software to regulate the use of lab space, as well as the digitization of brainstorming and meetings to maintain necessary collaboration across distances. Social distancing and lab cleanliness measures, such as unidirectional people flow in-lab, are likely to stay in some form for the foreseeable future as the international community continues to step down from the pandemic.

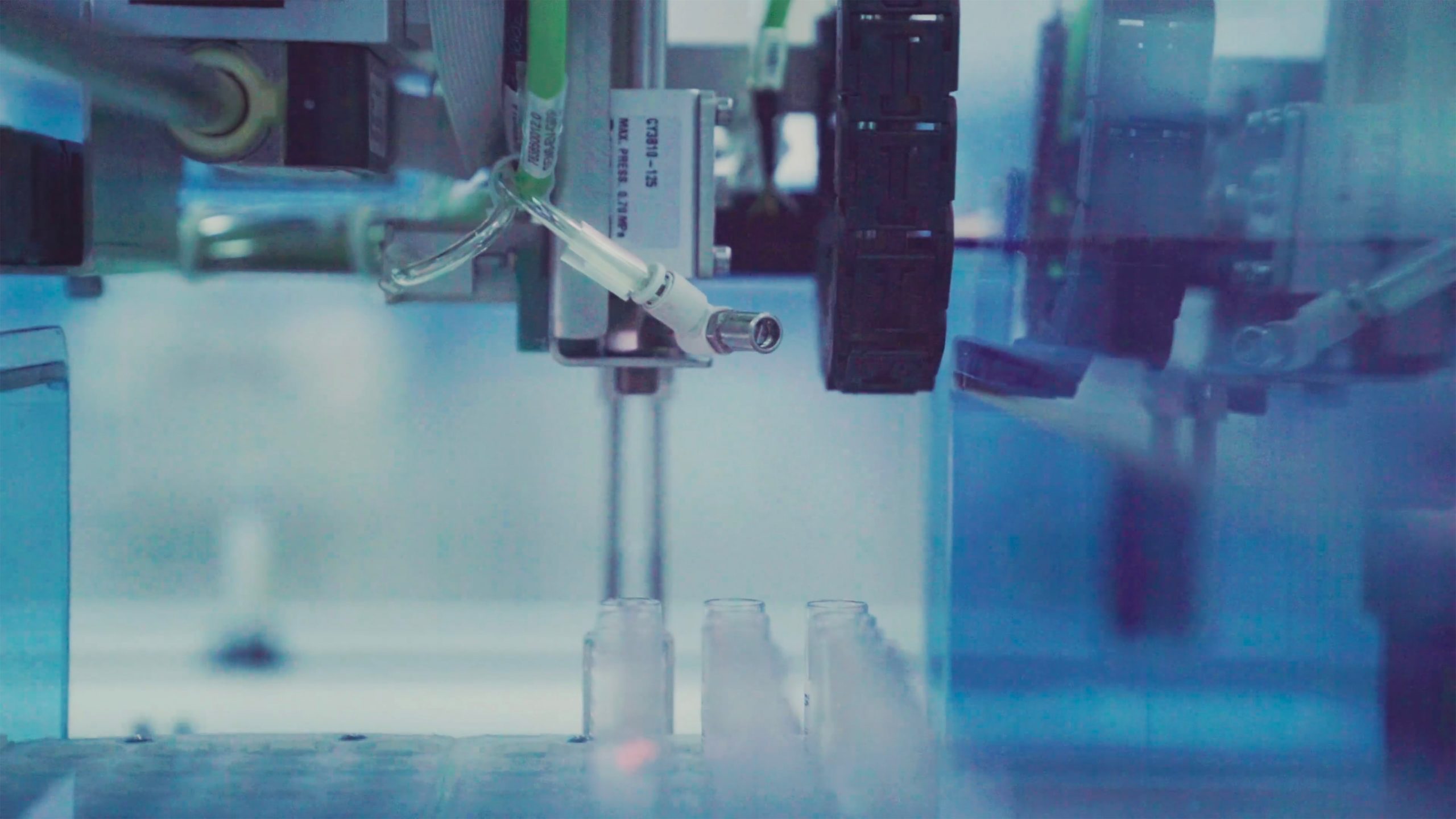

In terms of workload, projects need to be managed much more actively in order to ensure that output is maintained with fewer personnel in the lab at any given time. Staff that need to do bench work may set up rotation schedules, effectively booking out time to be in-lab. Similarly, on-site personnel capacities will be set. To this effect, automation gives a much-needed boost to bandwidth, allowing high volume tasks to be completed more quickly, and without using up valuable staff time on-site. The restrictions on lab operations entailed by the COVID-19 pandemic have given rise to advances in tech-enabled workflows, notably in life sciences. IBM notes a couple of cases here, such as investigators extracting data from patient wearables for clinical trials, and providers connecting remotely to patients and investigators.

Going forward, we are likely to see a continued emphasis on at-home sampling to reduce unnecessary person-to-person contact. For example, the Children’s Hospital of Seattle innovated a dried blood test for the measurement of the immunosuppressant drug tacrolimus. Patients are able to collect a sample of capillary blood using an at-home kit, comprising a fingerstick and filter paper, which is subsequently sent to the lab for testing. As the presence of this drug in a patient’s system makes individuals vulnerable to infection, the ability to conduct this test remotely greatly improves patient safety.

How Automation and Process Innovation Are Changing Lab Operations

Social distancing restrictions and work from home mandates have accelerated the uptake of cloud computing in labs, with a need to transfer and store large quantities of data and enable remote access. The automation of data analysis tasks helps to organize and rationalize large volumes of information while reducing the need for staff to attend the lab to perform analytics. One COVID-related innovation case study is Clear Labs’ genome sequencing instrument, which combines sequencing, robotics, and cloud-based analytics. Having been developed initially for food safety tasks, it was redirected during the pandemic. Automating the sequencing process with machinery saves between two and three days for preparatory work, and anywhere between four and ten days for analysis. Other innovations include remote pH and temperature-sensing stir-bars, and remote centrifuge control. To facilitate remote instrument operation, labs may turn to management software platforms that provide a central secure interface for remote monitoring and control of lab processes.

With the changes mentioned in lab operations in a post-COVID landscape, demand has increased for smaller, simpler, and cheaper lab automation. Formally, lab automation worked as a more niche solution for large-scale labs dealing with high throughput. However, with labs of all sizes now having to deal with reductions to on-site capacity, staffing shortages, and stringent cleaning and distancing regulations, more accessible types of automation are seeing greater rates of adoption. Small and medium labs also stand to benefit substantially from automation, but cost acts as a barrier to entry. As such, smaller and less flexible but more affordable bench-top automation systems are becoming more popular – such as the Opentrons liquid handler system. Smaller and less expensive systems are designed to automate a specific task, in contrast to fully automated systems that are more costly, but deal with higher throughputs and are more flexible.

Lab Digitization Post-COVID-19

Lab Digitization Post-COVID-19

The pandemic has seen considerable acceleration of the digitization processes in labs, as companies have had to adapt to in-person restrictions and aim to be better prepared for any future disruptions. Simon Meffan-Main, VP of product at Tetra Partner Network, relates a conversation with executives from a top ten pharmaceutical company, who previously “had a plan for digital transformation that was going to ride over the next five years. [They] are now compressing that plan into the next 18 months.” He identifies the present wave of digital transformation and automation as the post-pandemic focus for biotech and pharma companies, as the industry seeks to foster resilience and institute robust systems for better handling of any future pandemics.

A key offshoot of this digitization is improvements in data liquidity in order to accommodate easier and more effective collaboration between companies in the future. While the pandemic saw heightened collaboration across the industry, efforts may have been hampered by difficulties in sharing data. Data that is kept in different formats can be indecipherable without use of the correct technology, and this may even slow data sharing between different departments of the same company – with this difficulty compounded in sharing data between companies. Thus, a greater focus on digitization moving onwards will increase the ease of collaboration and data sharing. A poll conducted at a conference by the Pistoia Alliance, a global not-for-profit advocating for greater collaboration in life sciences, reports that 72% of attendees believe the lab of the future will be at least 50% virtual by 2030. This reflects changing attitudes in the industry towards the importance of digitization, and a recognition of its increasingly important role in building operational resilience and creating efficiencies.

While the pandemic has presented labs with no shortage of challenges, hardship has given rise to innovation in lab processes, changing conceptions about what can be achieved through remote working and how automation can create efficiencies as we move into a post-COVID norm. One of the principal benefits of the restrictions imposed on lab workers has been an enhanced atmosphere of collaboration across the sciences, with innovations in lab digitization set to ease data sharing and cooperation into the future.

TubeWriter: Automation to Get the Most Out of Your Lab

In a landscape of substantial staff shortages, staff time in the lab is more valuable than ever. Using TubeWriter to label your labware frees up your important resources – helping you keep up with high sample volume and allowing your staff to focus on higher value objectives. Get in touch today to find out how our labware printing system can increase your lab’s adaptability and resilience.