If you’ve worked in a laboratory setting, you know just how chaotic these environments can be. Not only are there tons of materials to keep track of, but you’re also expected to move at a fast pace. To help prevent mistakes, many labs emphasize the importance of proper labeling.

In an efficient lab, nearly everything — from tubes and vials to cassettes and microplates — needs to be labeled accurately. When a material is missing a label or tagged incorrectly, it can lead to critical errors that cost time, money and resources. In this article, we review the importance of labeling and how direct printing on labware can help streamline your workflow.

The Importance of Proper Labeling in the Lab

From life science research to healthcare clinical laboratories, there are several major industries that rely on high-quality, accurate laboratory testing. Even one small labeling mistake can have serious repercussions. Here are just a few reasons why proper labeling is essential:

- it improves accuracy

- it promotes efficiency

- it increases safety

First, correct labels boost accuracy by telling you what a material is and its current condition. For example, labels inform lab staff if a sample is expired or should not be used. They also help ensure every material is going to the right place, which saves time and promotes efficiency. Finally, proper labeling increases safety. It’s estimated that over 70% of medical decisions are determined by lab results — this means a single error can significantly delay a patient’s treatment.

It’s safe to say that when it comes to labeling labware, you want everything to be as accurate as possible. Unfortunately, when you leave labels to human hands, they’re vulnerable to errors like illegible handwriting, incorrect labeling and misplacement. That’s why more facilities are turning to direct printing.

Benefits of Direct Printing on Labware

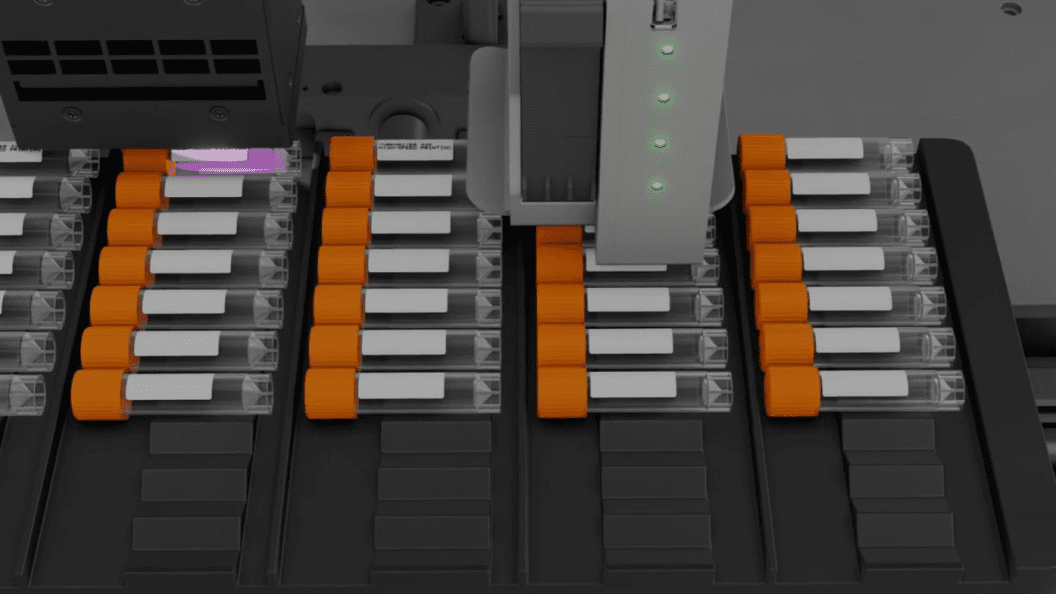

As the name suggests, direct printing involves using an automated system to print labels directly onto the surface of tubes, vials and other laboratory materials. Unlike hand labeling, it doesn’t require using markers or pens, or even adhesive labels, which greatly reduces the risk of human error. Let’s take a closer look at some of the unique benefits of direct printing on labware.

Enhanced Readability

When you’re conducting research, it’s essential to work with accurate information. Direct printing improves accuracy by enhancing readability. Rather than worry about sloppy handwriting, you can relax knowing every label is clear and legible. In addition to improving accuracy, this helps improve sample tracking and prevent sample loss due to human error, which in itself is costly.

Increased Speed

Scientific research requires many tests and a lot of specimens. Repetitive manual labeling is time consuming and adds more time to the experiment process. To save time, use high-speed automated direct printing on labware like tubes and vials. By imprinting labels directly onto the surface of containers, it eliminates the need for tedious writing and hand labeling.

Better Efficiency

When you’re working in a fast-paced atmosphere such as a lab, efficiency is key. Direct printing streamlines workflow and promotes efficiency by simplifying the labeling process. Instead of sorting through sticky labels and trying to pick out the right sizes, you can just let automation handle the problem. And, since labels are printed directly onto materials, you don’t have to worry about sticky labels falling off or jamming machines.

Improved Quality

One of the biggest drawbacks of handwritten labels is that they’re vulnerable to external elements. Handwriting can get smudged, labels can fall off and change in temperatures can affect adhesives. Direct printing with a solution like TubeWriter, on the other hand, is much more resilient. Our automated tube labeler ink has the following features to maintain sample integrity:

- Alcohol resistance

- Formalin resistance

- Temperature/solvent resistance

- Waterproof

To boost durability, direct printing with TubeWriter incorporates industrial Inkjet technology. It’s also tested multiple times to ensure it can withstand harsh, industrial conditions. This is especially useful when placing items in cryogenic or long-term storage facilities.

Reduced Costs

Last but not least, direct printing can reduce costs in the long run. Consider a direct printer like TubeWriter to be an investment for your lab; you’ll end up saving money on labels and writing tools in the long run. You also don’t need people to write and apply the labels, giving your staff a break from the monotony of tube labeling and more time to focus on the science.

Direct Printing Barcodes on Labware

While you can hand-label lab materials with names or dates, you can’t write out a barcode. Direct printing with TubeWriter has an additional benefit: it lets you print barcodes straight onto containers. You can even integrate barcode scanners into your benchtop automation to read tubes and collect data for your systems. Here are the barcode types that TubeWriter supports:

- Data matrix

- Linear

- 2D

- Code 128

This feature is especially useful in biosciences. For instance, you could add standards-based barcodes to cell bank vials to help ensure accurate specimen identification or even print on tiny PCR tubes. And, as an added perk, direct printing with TubeWriter supports Laboratory Information Management System (LIMS) and Excel integration. Simply input text into the software, then sit back and watch it print onto your labware.

Direct Printing with TubeWriter

From improved efficiency and speed to reduced costs and errors, there are many benefits to using direct printing over hand labeling. Of course, for the best results, it’s important to rely on a quality system, such as TubeWriter. Our tried and tested, high-speed Inkjet technology has been used by a number of labs across the globe. It can label a wide variety of surfaces, including the following:

- Vial caps

- Container bodies

- Glass, plastic, metal and ceramic materials

In addition to versatility, you can expect impressive speeds. Depending on the media type, our product can print on eight to 96 tubes per run and up to 2,500 tubes per hour. It can also print up to five lines of data and cut labeling time by over 80%.

Ultimately, direct printing improves sample integrity, boosts lab throughput and gives you more time to focus on what matters: groundbreaking research and product development. Learn more by contacting us today!