Introduction to Cryovial Labels

We’ve all been there. It’s time to put your precious samples into the “deep freeze” of your laboratory freezers.

You spend weeks working to get the right samples (cells, tissues, etc.), aliquot them into pre-labeled cryovials, move them to dry ice bath containers, put the frozen vials into freezer boxes, and finally, put them into liquid nitrogen storage, only to come back a few months later to find that the labels are unreadable and that you wasted all that effort.

Let’s fix this!

When it comes to labeling cryovials for long-term storage at -80 C, you only have four solvent-resistant choices: Buying pre-labeled tubes (expensive!), writing the labels with a Sharpie (1970s tech), printing labels on adhesive sticky label sheets and sticking them, and directly printing the labels on the surface of the cryovial aka with a TubeWriter 300 or 400.

As you’re no doubt aware, it’s a desert wasteland out there trying to find information on the best labels for cryogenic vials.

Depending on availability, some equipment suppliers want to sell their expensive cryogenic vials. Others hide their problems until you install the big metal hunk on the bench.

What would help greatly is to find some unbiased information that explains each method in detail and then back off—letting a scientist make the final decision.

We want you to choose the best method for you and your lab (and your results!).

This article will compare and contrast the two most popular modern methods for cryogenic labels: adhesive labels and direct printing.

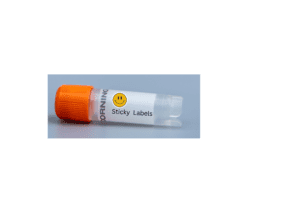

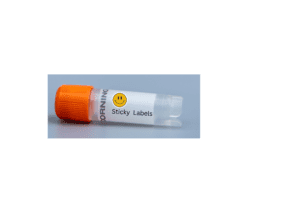

Adhesive Cryovial Labels

Additionally, sticky cryovial labels are easier to remove than permanent adhesive labels, making them a good option for mistakes in printed identification information.

Yet, employing adhesive labels for ultra-low temperature storage conditions presents distinct challenges. At such extreme temperatures, adhesives may become brittle and less adhesive, leading to labels falling off or deteriorating to the point you can’t read them.

This is a critical concern in long-term cryogenic storage, such as preserving biological samples for future genomic studies.

Label loss or damage risks compromising sample identification, potentially resulting in misidentification and negatively impacting the validity of longitudinal research.

Furthermore, the physical dimensions added by adhesive labels on vials should not be overlooked, especially in automated sample handling systems typical in high-throughput laboratories. These labs, often engaged in extensive drug screening, might face operational inefficiencies or equipment malfunctions due to the increased circumference from labeling. Have you ever tried jamming a labeled tube into those small centrifuge holes? It’s not pretty.

This necessitates meticulously evaluating the label’s thickness and adhesive quality to ensure seamless integration with laboratory equipment and storage systems. This underscores the importance of choosing the right labeling solution to maintain the precision and efficiency of research processes.

Finally, the cost implications of adhesive labels are another significant factor to consider. While adhesive labels offer numerous advantages regarding adaptability and compatibility with different vial types, they can be considerably more expensive. The cost of adhesive labels can be nearly ten times higher per tube than other labeling methods.

Balancing the need for reliable, versatile labeling against financial constraints is a crucial aspect of laboratory management, requiring thoughtful decision-making to optimize scientific and economic efficiency.

Direct Printing Cryovial Labels

This technique negates risks like label detachment or smearing by bypassing adhesives, thus guaranteeing the labels’ longevity and legibility.

A key benefit of direct printing is its cost-effectiveness over time. While initial investments are required to acquire specialized printing equipment, the recurring expenses are relatively modest.

In laboratories processing thousands of samples yearly, this translates to a marked reduction in cost per label, offering significant savings over adhesive or pre-barcoded labels.

Furthermore, the enduring nature of direct printed labels means replacements are less frequent, further diminishing long-term costs.

Direct printing is particularly beneficial for high-throughput labs, where handling a large number of samples is routine. This method’s efficiency enables rapid processing of extensive batches without sacrificing label quality.

Direct printing also aligns with environmental sustainability by reducing waste associated with backing paper and adhesives used in traditional labels. Moreover, it circumvents the risk of adhesive contamination, fostering a safer work environment for laboratory staff. This aspect of direct printing contributes to operational efficiency and demonstrates a commitment to environmental responsibility and workplace safety, aligning with the broader goals of responsible scientific practice.

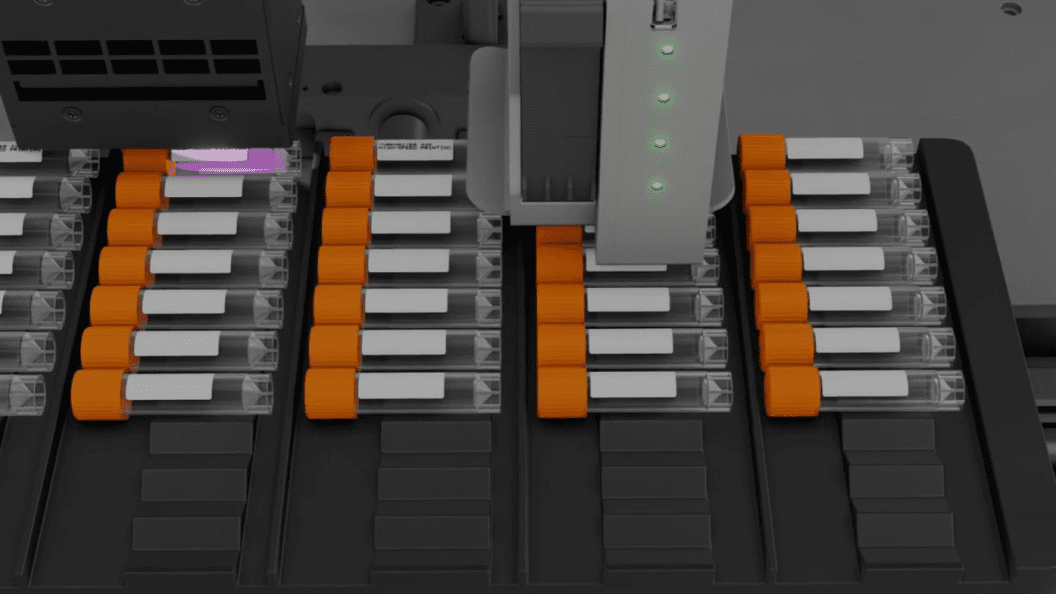

One place direct printing is not a great choice is if you’re labeling thousands of cryogenic vials per day and need to fully automate the process. Printers like Scinomix are probably your best bet for this automated sticky label (though, again, you need to be aware that some of the labels will fall off from time to time).

Customizing Cryogenic Labels

Both direct printing (with a TubeWriter) and adhesive labels allow you to print text, barcodes, and images directly onto cryogenic vials.

Most cryovials have a very obvious white space for labeling, so whatever fits in that space is fair game for customization with a direct printer.

So, for example, if you can’t fit a really lengthy line of sample identification in that white space, adhesive labels are your best bet. Visiting a manufacturer’s website should give you more information.

Jamming and Messiness with Cryogenic Labels

When you apply a barcode label to a tube, you increase the tube’s diameter with the paper label’s width. Many centrifuges will reject a tube with a label, so consider this before using an adhesive label.

Also, when using a glove, if any part of the adhesive touches any part of the glove, it will usually rip the glove or at least ruin the label.

One place to be careful with cryogenic labels is in a dry ice bath! Using ethanol at too high a concentration can affect any ink on the market, so have a good understanding of your surfaces and solvent resistance!

Automated adhesive label machines – warning note – Because automated adhesive label applicators robotically handle the gooey adhesive labels, they jam often enough to need human tending.

Wrapping it Up. – Cryovial Labels Comparison

Any tube marking method should be carefully considered. Most labs will benefit from a TubeWriter direct printer, which is very flexible, works with any tube, prints text and barcodes, and has a low consumable cost. However, it may cost some money upfront.

TubeWriter is a leading manufacturer of direct lab consumable printers. We are used by almost every top biomedical firm in the world. If you’re interested in making custom samples or getting a standard sample pack, contact us today.