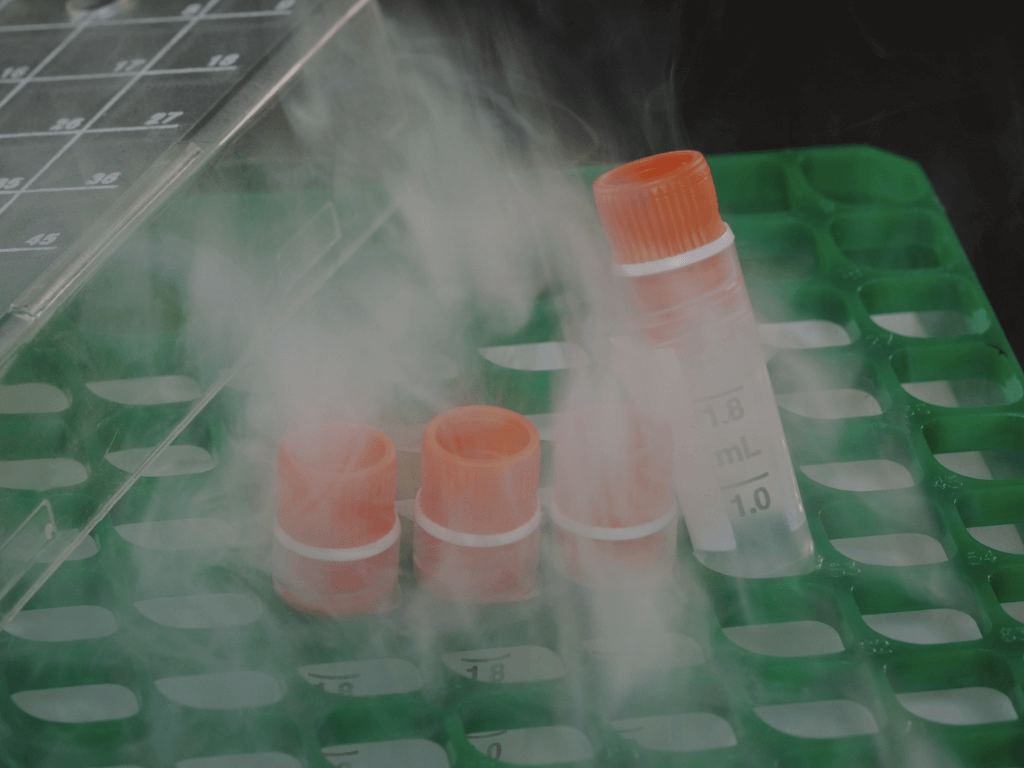

Labeling frozen cryogenic tubes is a common challenge in many laboratory settings.

Traditional labeling methods, such as adhesive labels or hand-writing on the tube with a marker, are often insufficient when labeling tubes that are already frozen.

However, cap labeling has emerged as a reliable solution to this issue.

By labeling the caps of frozen tubes, samples can be easily identified, eliminating the risk of confusion or misidentification that can occur when traditional labeling methods fall short.

In this article, we will delve deeper into the challenges of labeling frozen specimens and how cap labeling can help alleviate them.

Challenges with Adhesives in Extremely Low Temperatures

One of the main challenges is that the extreme cold temperatures of cryogenic storage can make it difficult for adhesive labels to stick properly. Many traditional adhesives, such as those used on paper labels, may become brittle over time and lose their stickiness at low temperatures when applied before cryo storage. This can result in labels becoming detached, making it difficult to identify the samples inside the tubes, and the need for re-labeling or even sample loss.

If the tube is already frozen, however, re-labeling becomes more challenging with adhesive labels. The tube surfaces may be frosted, and the frozen water droplets can create a barrier to proper adhesion. This makes it difficult for the adhesive to bond properly to the surface, resulting in the same issue of labels lifting or falling off. Even if you are relabeling and placing a label over the previous label, this changes the thickness of the tube and can interfere with how a tube fits into a rack or machinery, resulting in jams.

Illegible or Flaking Handwritten Labels

Using markers to label cryogenic tubes after they are frozen can also be tricky. Specialized cryogenic markers have been developed, but handwritten labeling, particularly if written over a frosted surface, can be illegible and cause problems with sample tracking. Using markers to label cryogenic tubes after they are frozen requires careful attention to the type of marker used, the surface of the tubes, the ink formulation and the storage conditions.

Cap Labeling for Frozen Specimens

Labeling the cap rather than the tube or vial eliminates the challenges of labeling frozen specimens. Along with the many benefits of cap labeling, you don’t have to worry about printing onto a frosted surface. Through direct printing with TubeWriter, you can include more information on the small surface of the cap than if you were to write by hand. There are two ways that labs often handle cap labeling with TubeWriter:

- Cryogenic vial cap inserts for recessed caps.

- Replacing the cap with a printed one.

Cap Inserts

Cryovial cap inserts easily pop into recessed caps for identification. This makes them ideal for labeling specimens without changing the cap, as long as the existing cap is recessed. While some labs used colored cap inserts to identify specimen groups, TubeWriter can actually print ID numbers or 2D barcodes on them. This way you can store more information about the specimen directly on the container.

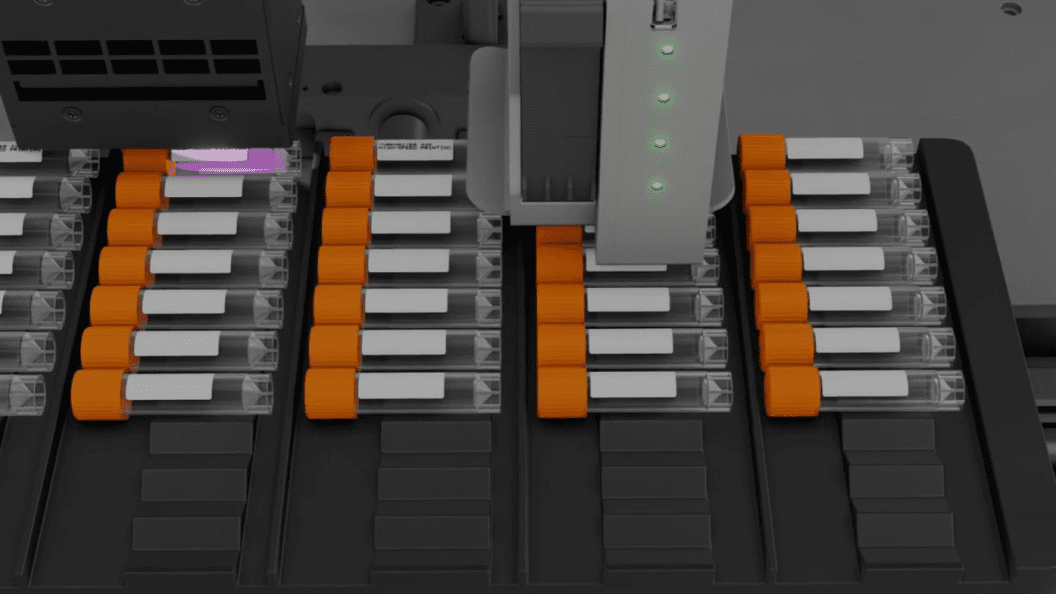

New Caps

The alternative to cap inserts is labeling a whole new cap and replacing the existing one. Labeling the cap with 2D barcodes is particularly beneficial for frozen specimens because you won’t have to handle the tubes and take them out of the rack or box to scan them. TubeWriter can even print barcodes in recessed caps.

Direct Printing for Labeling Frozen Tubes

Printing directly onto frozen cryovial caps has a number of benefits over the traditional labeling methods. It is much more efficient than using adhesive labels or hand-labeling with pens. Direct printing on the specimen cap creates a permanent, tamper-proof label that can withstand extreme temperatures, as well as exposure to chemicals and other harsh conditions. You no longer have to worry about whether your labels stay put or if they are going to cause jams.

Overall, printing directly onto frozen cryogenic tubes before freezing or onto new caps or cap inserts once frozen offers significant benefits over traditional labeling methods. It’s a great way to ensure accurate and secure sample identification, which is critical for scientific research, clinical diagnostics, and other applications.