Have you ever wasted time removing tubes from their racks, just so you could get a glimpse of the label on the side? Or, have you ever struggled to apply an adhesive label to a frozen tube or recessed cap? To avoid these issues, more and more scientists are turning towards cap labeling.

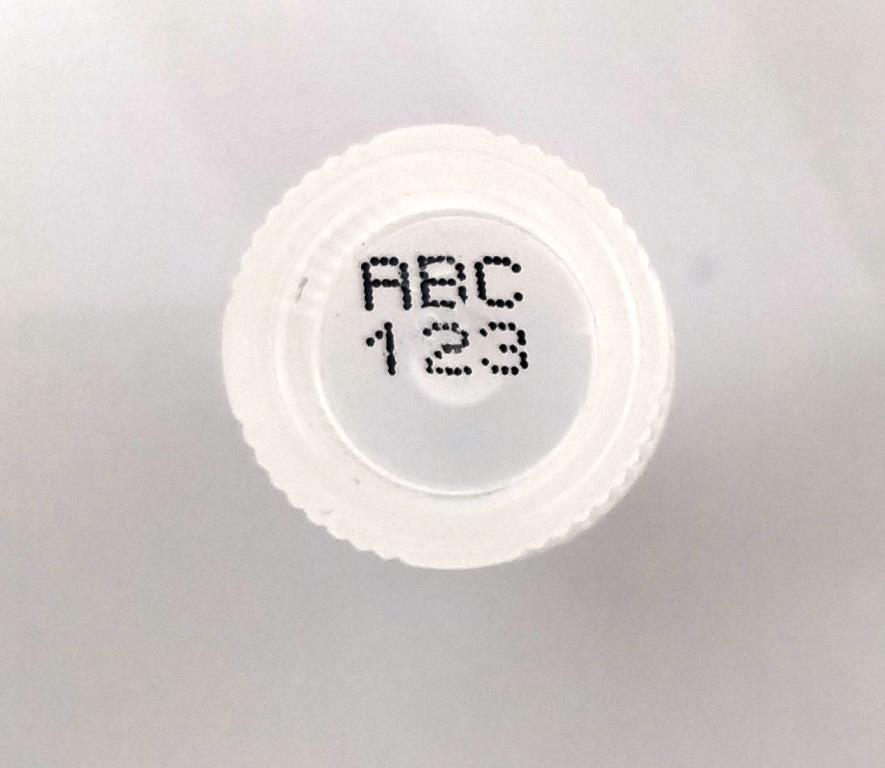

Using a resource like the TubeWriter, you can print labels directly onto tube and vial caps, eliminating the need for tedious, handwritten labels. Let’s take a closer look at the benefits of cap labeling, its applications and how the TubeWriter can help improve efficiency.

What Are the Benefits of Cap Labeling?

Here are a few top benefits of cap labeling for tubes and vials in the lab.

Save Time

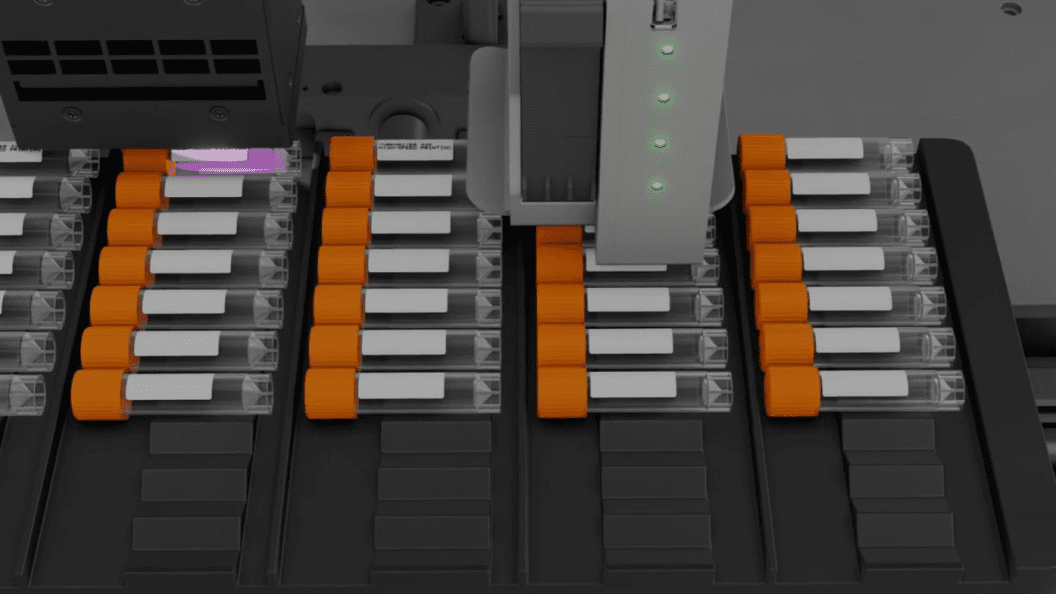

One of the biggest advantages of cap labeling is the amount of time it saves. Not only is printing with the TubeWriter faster than writing by hand, but you also don’t have to worry about delays due to confusing, illegible handwriting. Not to mention, vials and tubes don’t need to be removed from the freezer or rack for identification — all you have to do is look at the caps. The more time you save, the faster you can get results.

Improve Accuracy

In addition to saving time, cap labeling can improve accuracy by ensuring every specimen is tagged legibly and correctly. It’s also helpful as a secondary identifier. Even if you already have an adhesive label on the side of the container, it doesn’t hurt to include a label on the cap. This helps ensure the cap and tube have the same sample ID and lowers the likelihood of caps getting lost or being placed on the wrong tube.

Stronger Resistance

From extreme temperatures to substances like water and alcohol, there are several elements that can harm adhesive labels. For example, water may smudge handwriting, while high temperatures can melt the adhesive. By using the TubeWriter to directly print labels onto caps, you can lower the risk of external damage to labeling.

Prevent Jams

A common issue with sticker labeling is the potential for jams. Adhesive labels on centrifuge tubes may fall off, especially if the sample is frozen or has ice crystals on the outside. As a result, tubes might jam the centrifuge, which delays your project and forces you to deal with a jammed machine. Since cap labeling involves directly printing onto tube caps, you don’t have to worry about any labels falling off or causing jams in machinery.

Quick & Accurate Identification

When you’re handling multiple samples for different experiments, accurate identification is extremely important. That’s why many scientists mark caps with symbols or key identifiers. Not only are symbols on caps easy to see, but they also let you provide more information without crowding the tube’s primary label. With a resource like the TubeWriter, you can quickly install identification markers along either the cap’s ridges or sides.

What Can I Use Cap Labeling For?

While cap labeling can be utilized for any tubes or vials, it’s especially useful for items that are inconvenient to label by hand, such as the following:

- Frozen specimens: As mentioned earlier, adhesive labels are more likely to fall off when the specimen is frozen or has ice crystals. Although the TubeWriter cannot print on frozen surfaces, it can print on cap inserts — these can then be applied to frozen vials.

- Recessed caps: A recessed or indented cap is nearly impossible to label by hand. However, it can be printed on with the TubeWriter or you can print on a small cap insert for the indent.

- Filled tubes: When you turn a filled tube on its side to attach an adhesive label, the liquid may touch the cap and contaminate the sample. With direct cap labeling, you don’t have to risk flipping the tube to apply a label.

- Microcentrifuge tubes: To label a microcentrifuge cap by hand, you must either flip the tube down and hold the cap against a desk, or pop the cap on and hold the vial while writing. In addition to being inconvenient, these processes increase the risk of contamination. Cap labeling with TubeWriter, meanwhile, allows you to easily place the lid on before printing directly.

- Transitory processing tubes: The journey a sample takes to reach its final container involves many steps (and sometimes tubes). If you have minimal information that needs to go on a transitory processing tube, such as numbers, you can save time and improve efficiency by printing a quick cap label.

Ultimately, cap labeling allows you to label many items that would be difficult (or even impossible) to label through handwriting.

Interested In Cap Labeling? Try TubeWriter Today!

Whether you’re struggling to label frozen specimens, improve sample integrity, or simply want to boost accuracy and speed, cap labeling is a great resource. If you’re looking for a reliable, quality method to perform cap labeling, TubeWriter is here to help. Our unique Inkjet technology, which has been featured in laboratories and industries across the world, can apply legible labels on any vial or screw caps. In addition to accuracy, you’ll enjoy high speeds, convenience and improved specimen identification. Interested in learning more? Don’t hesitate to contact us today!